Validation of sealing equipment

INTRODUCTION

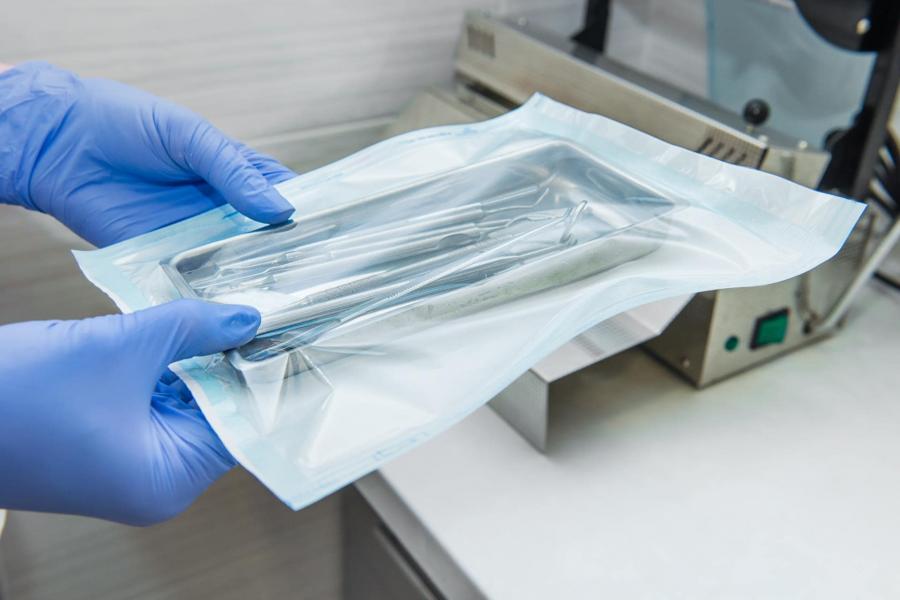

Laminated bags in healthcare institutions and pharmaceutical companies must be carefully sealed to store a product in a sterile state. To demonstrate that your laminated bag sealing equipment is functioning properly, you must have it validated periodically. Bureau Veritas can carry out this validation accurately on your behalf.

Bureau Veritas' Validation & Monitoring department was established in 1985 from Krachtwertuigen (Kwant) and later KW2. Due to our extensive experience involving process validations, you are assured of a professionally executed procedure. And with our team of ten highly skilled validation technicians, we can plan flexibly.

SCOPE

We validate sealing equipment in the medical sector and pharmaceutical industry when required or desired.

STANDARD CONTENT

The EN868-5 standard applies to the validation of sealing equipment.

VALIDATION PROCESS

What does the validation process look like? First, we draw up an audit plan with you as a client/user. The validation technician seals a number of laminated bags during validation. The research into the tensile strength of the laminate bags is outsourced to Interster International in Wormerveer. Within twenty working days, you will receive a final report containing all findings and conclusions.

ACCREDITATION

Bureau Veritas' Validation & Monitoring department is accredited as an ISO/IEC17020 type A inspection body. This means the validation we perform is completely independent. In addition, our validations are periodically assessed by the Dutch Accreditation Council (RvA - Raad voor Accreditatie) and by various certification bodies. On the RvA website, you will find the scope of the work areas for which we are accredited.